Product Description

Founded in 2018, HangZhou Industry & Trade co., LTD is mainly aimed at overseas markets, the factory was founded in 2005, it has been a professional manufacturer of caster wheels for more than 17 years. And thanks to the efforts of our entire staff, our 2 brands Mingwei & Xihu (West Lake) Dis.g become very CHINAMFG brands in China’s caster industry and overseas. Now, our factory has more than 200 workers and covers an area of 35000 square meters. The annual output value has reached 100million. And they are sold to nearly 40 cities in China and exported to Southeast Aisa, Europe and other places.Our main products are: Light Duty, Medium Duty, Heavy Duty, Extra Heavy Duty Caster, Pneumatic caster, shock absorption, stainless steel wheel, scaffolding, medical wheels, Plastic Trolleys, stainless steel trolleys, square tube trolleys and other products, totally more than 50 series and 1000 types products for your choice. And they are widely used in industrial, commercial,household appliances, furniture, packing, transport, warehouse, medical and other fields.Besides, we have our own R&D team and could offer OEM service for clients. And delivery time is 2 weeks normally. We believe a professional and high Efficient business partner will be always your best choice.We regards “reasonable prices, efficient production time and good after-sales service” as our tenet. Any require and cooperation are warmly welcomed,we hope to cooperate with more customers for mutual development and benefits.

Product Description

| Light Duty Stem Casters with Brake 2 Inch PP | |

| Size | 2 inch |

| Application: | carts, trolley,kitchen equipment,Furniture, forklift, hand cart |

| Caster material: | PP |

| Wheel width: | 22mm |

| Load capacity: | 35kg |

| Thickness: | 2mm |

| Wheel Diameter: | 50mm |

| Load height: | 65mm |

About CHINAMFG Casters

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Stem Casters |

|---|---|

| Wheel Material: | PA+ABS |

| Brake: | With Brake |

| Bearing Type: | Plastic PP |

| Surface Treatment: | Zinc Plated |

| Brand: | Other |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-03

China Custom 2″ European Type Plastic Twin Wheel Trolley Wheel

Product Description

WBD Caster Manufacturer 20+ years:

2″ European Type plastic Twin Wheel Trolley Wheel

Product Description

Product Parameters

|

Size |

Wheel diameter |

Load capacity |

Top-Plate size |

Bolt hole spacing |

Bolt hole |

Overall height |

|

2inch |

50*20mm |

70 |

60X60X2 |

46X46 |

12 |

71.5mm |

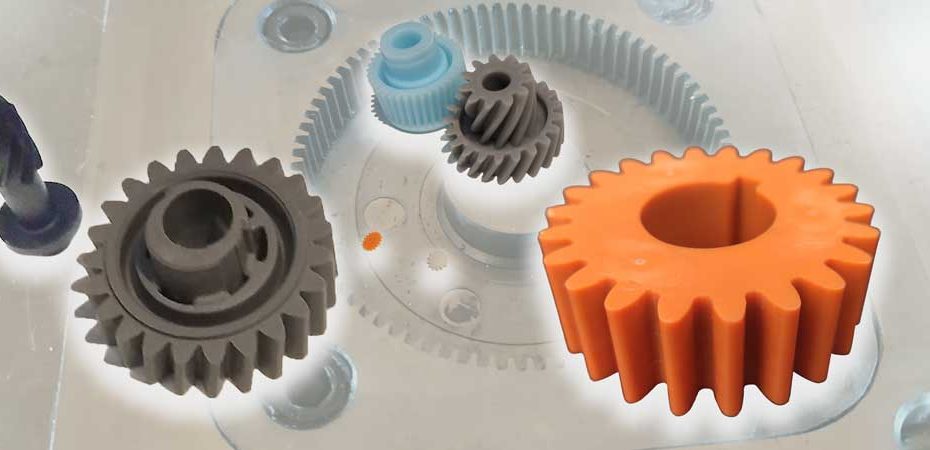

Characteristics of different material casters

1. PU casters: Whether the casters work indoors or outdoors, they can meet your requirements.

2. TRP casters: They can be used in the situations that require less noise and work quietly, like working in hotels, on medical equipment, on floors, on wooden floors, on tile floors ….

3. Nylon casters and iron casters: The casters are suitable for the places where the ground is uneven or where there are iron scraps on the ground.

4. Rubber casters: The casters are inappropriate under the condition of acid, grease and chemicals.

5. Pneumatic casters: The casters are suitable for light load and the uneven roads .

In order to meet the market demands, we always keep paying attention to improving and developing our products and ourselves. Currently we offer more than 2000 different kinds of high quality casters combinations for almost every applications such as: industrial machine, medical facility, furniture, trolley, shopping cart, hand pallet, scaffolding, shelf and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Rotating Wheel |

|---|---|

| Wheel Material: | Plastic |

| Brake: | With Brake |

| Samples: |

US$ 2.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What advantages do plastic wheels offer in terms of corrosion resistance and longevity?

Plastic wheels offer several advantages in terms of corrosion resistance and longevity, making them a preferred choice in various applications:

- 1. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion. Unlike metal wheels, which can rust or corrode when exposed to moisture or harsh chemicals, plastic wheels do not rust or corrode. This corrosion resistance is especially valuable in wet or corrosive environments.

- 2. Chemical Resistance: Plastic wheels can withstand exposure to a wide range of chemicals, acids, and solvents without deteriorating. This resistance to chemical damage extends their lifespan when used in environments where chemical spills or exposure is a concern, such as in laboratories, manufacturing facilities, or healthcare settings.

- 3. Moisture Resistance: Plastic wheels are not affected by moisture, making them suitable for outdoor applications or environments with high humidity. They do not absorb water, preventing swelling, warping, or degradation due to moisture exposure.

- 4. UV Resistance: Some plastic materials used for wheels are UV-resistant, which means they can withstand prolonged exposure to sunlight without degrading or becoming brittle. This quality is beneficial for outdoor applications, including lawn and garden equipment.

- 5. Longevity: Plastic wheels are designed for durability and a long service life. High-quality plastics, reinforced designs, and proper maintenance contribute to their longevity. They do not suffer from wear and tear like rubber or pneumatic tires and can maintain their performance over extended periods.

- 6. Low Maintenance: Plastic wheels typically require minimal maintenance. They do not need lubrication, and their surfaces are easy to clean. This reduces the need for ongoing maintenance, saving time and resources.

- 7. Lightweight: Plastic wheels are lightweight compared to many metal alternatives. Their reduced weight places less stress on equipment, reducing wear and tear and contributing to their overall longevity.

- 8. Non-Marking: Some plastic wheels are designed to be non-marking, meaning they won’t leave scuff marks or damage flooring surfaces. This feature is valuable in applications where protecting the floor’s appearance is important.

- 9. Floor Protection: Plastic wheels, especially those with softer materials or specialized coatings, provide excellent floor protection. They are gentle on surfaces and do not scratch or dent floors, making them ideal for indoor use.

Overall, the corrosion resistance and longevity of plastic wheels make them an excellent choice for applications where environmental factors, chemicals, or moisture could compromise the performance and lifespan of other wheel materials, such as metal or rubber.

How does the choice of plastic wheels affect the overall performance and reliability of rolling systems?

The choice of plastic wheels significantly impacts the overall performance and reliability of rolling systems across various applications. Here’s how the selection of plastic wheels influences these factors:

- 1. Load Capacity: The choice of plastic wheels with the appropriate load capacity is essential. Wheels that can adequately support the intended loads ensure the system’s reliability and prevent premature wear or failure due to overloading.

- 2. Material Selection: Different plastic materials offer varying levels of durability, resistance to environmental factors, and chemical resistance. Selecting the right plastic material for the specific application ensures long-term reliability and performance.

- 3. Smooth Rolling: High-quality plastic wheels with precision bearings offer smooth and consistent rolling motion. This smoothness improves the efficiency and reliability of rolling systems, contributing to reduced wear and lower maintenance requirements.

- 4. Noise Reduction: Plastic wheels are known for their quiet operation due to low friction and noise-dampening properties. Choosing plastic wheels with noise reduction features enhances the comfort and usability of the rolling system, particularly in noise-sensitive environments.

- 5. Floor Protection: Plastic wheels are less likely to damage or mark flooring surfaces compared to metal or rubber wheels. This protection ensures the reliability of indoor rolling systems by preserving the appearance and integrity of floors.

- 6. Resistance to Environmental Factors: Plastic wheels can be selected based on their resistance to environmental conditions, such as moisture, chemicals, and temperature extremes. Choosing wheels with appropriate resistance ensures reliable operation in challenging environments.

- 7. Longevity: High-quality plastic wheels are designed for durability and extended service life. They resist wear and degradation, reducing the frequency of replacements and enhancing the long-term reliability of rolling systems.

- 8. Weight Reduction: Plastic wheels are often lighter than metal alternatives. This weight reduction can improve the efficiency of rolling systems by reducing energy consumption, especially in applications like automotive and aerospace.

- 9. Customization: Plastic wheels can be customized to meet specific requirements, including size, load capacity, and tread design. Customization ensures that the wheels are optimized for the unique needs of the rolling system, enhancing overall performance and reliability.

- 10. Safety: Properly selected plastic wheels provide stability and safety to rolling systems, reducing the risk of accidents, equipment damage, and injuries. Reliability in safety-critical applications is paramount.

In summary, the choice of plastic wheels plays a pivotal role in determining the overall performance and reliability of rolling systems. Factors such as load capacity, material selection, smooth rolling, noise reduction, floor protection, resistance to environmental factors, longevity, weight reduction, customization, and safety considerations all influence the system’s ability to operate efficiently and dependably.

Can you explain the primary functions and applications of plastic wheels in various industries?

Plastic wheels serve essential functions in various industries due to their unique properties and versatility. Here are the primary functions and applications of plastic wheels in different industries:

- 1. Material Handling: Plastic wheels are widely used in material handling equipment, including carts, dollies, and conveyor systems. They provide smooth and noiseless movement, making them suitable for transporting goods in warehouses, factories, and distribution centers.

- 2. Office Furniture: Plastic wheels are commonly found on office chairs and furniture. They allow for easy mobility, quiet operation, and floor protection. These wheels are often made from soft materials like polyurethane to prevent damage to flooring.

- 3. Automotive: In the automotive industry, plastic wheels are used for various applications, including caster wheels on tool carts, wheels for automotive jacks, and even lightweight spare tire wheels. They offer a balance of durability, weight savings, and cost-effectiveness.

- 4. Retail and Shopping Carts: Plastic wheels are a staple in retail and shopping cart applications. They provide smooth and silent movement for shoppers while navigating stores. The lightweight nature of plastic wheels reduces cart weight, making them easier to push.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, such as hospital carts and medical devices. Their non-corrosive properties, lightweight design, and ease of cleaning make them suitable for healthcare settings.

- 6. Aerospace: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft.

- 7. Food and Beverage: Plastic wheels are found in food service equipment, including food carts, serving trolleys, and food processing machinery. They are resistant to moisture and corrosion, which is critical in food handling environments.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and easy adjustment for leveling RVs and trailers when parked.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications. They can be found on hand trucks, utility carts, and DIY furniture, offering ease of movement and floor protection.

- 10. Marine and Boating: Plastic wheels are used on boat trailers and marine equipment. They resist corrosion from saltwater exposure and offer buoyancy, making them ideal for marine applications.

- 11. Agriculture: In agriculture, plastic wheels are used on farm equipment, including wheelbarrows and agricultural carts. They provide durability and easy maneuverability in outdoor and rugged environments.

Plastic wheels are valued for their lightweight, corrosion resistance, cost-effectiveness, and adaptability across a wide range of industries. They play a vital role in improving mobility, efficiency, and performance in various applications.

editor by Dream 2024-05-03

China best Hot Sales 608 Bearing Roller Single Convex Roller, Plastic Window Roller Wheel with Housing

Product Description

Product Description

Company Profile

ZheJiang CHINAMFG Bearing Group is a professional bearing manufacturer and exporter in China. We have been engaged in bearing industry for 20 years.

Our company is specialized in producing Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings and Special Bearings in accordance with Customers’ designs.Our bearings has been widely applied into agricultural equipments, home appliances, power equipments, machine tools, automotives and engineering machinery, etc.

Our Products

Our main products include:

1,Miniature Bearings: like 608, 609, 625, 626, 693, 695, etc;

2, Deep Groove Ball Bearings: like 6000, 6200, 6300, 6800, 6900, 16000 Series;

3,Non-Standard Bearings: U grooved bearings, V grooved bearings, double grooved bearings, bearing rollers with or without plastic injection;

4,Pillow Block Bearing: UCP/ UCF/ UCFL;

5,Tapered Roller Bearings

6,Linear Motion Bearings

Packaging & Shipping

1 Plastic bag + Paper carton+ pallet

2.Single Box + Plastic rolling packing + Plastic bag + Paper carton+pallet

Our Factory

Our factory starts production from raw materials. We have a 20-person R&D team and launch a new product every 5 days. We have more than 600 people to produce bearing team, we produce products, the price is the most competitive in China.

Certifications

Why Choose Us?

1. Sample: (1). If you worry about our quality before ordering, we can supply you our current samples for free to check our quality (2). After finishing the mold: we would supply the samples for your approval before mass production ensure everything is perfect.

2. OEM / ODM service OEM & ODM ar highly welcomed, we provide full technical support for free.

3. After-sales service 100% responsible for our products, supply active feedback within 24 hours and solutions in short time; supply re-work or refund if the mistake cuased by us.Looking for ideal Skateboard Bearings 6082RS Manufacturer & supplier ? We have a wide selection at goods prices to help you get creative. We are China CHINAMFG Factory of Bearing . If you have any question, please feel free to contact us.

Our Activities

Contact Us

Stefanie

ZheJiang CHINAMFG Bearing Co., Ltd.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.05/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the performance of plastic wheels in different settings?

The choice of materials significantly impacts the performance of plastic wheels in various settings. Different plastics offer unique properties that make them suitable for specific applications and environments. Here’s how material choice affects plastic wheel performance:

- 1. Durability: High-quality plastics like polyurethane and nylon are known for their durability. They resist wear and tear, making them ideal for heavy-duty settings, such as industrial equipment or manufacturing environments.

- 2. Load Capacity: The material’s strength and rigidity influence a plastic wheel’s load-bearing capacity. Reinforced plastics or materials like glass-filled nylon can handle heavier loads compared to softer plastics like polypropylene.

- 3. Chemical Resistance: Certain plastic materials, such as polypropylene, offer excellent chemical resistance. They are suitable for applications where exposure to chemicals or acids is a concern, like laboratories or chemical processing plants.

- 4. Temperature Tolerance: Some plastics are designed to withstand extreme temperatures. For example, acetal (POM) wheels can handle both high and low-temperature environments, making them suitable for freezer or high-heat applications.

- 5. Moisture Resistance: Plastics like polyurethane and nylon are moisture-resistant and do not absorb water. This property ensures that the wheels remain functional even in wet conditions, such as outdoor use or in humid environments.

- 6. UV Resistance: UV-resistant plastics can endure prolonged exposure to sunlight without becoming brittle or degrading. This feature is essential for outdoor applications like lawnmowers or garden equipment.

- 7. Non-Marking: Soft, non-marking plastics are used in applications where floor protection is crucial. These wheels prevent scuffing or damage to delicate flooring surfaces.

- 8. Weight: The choice of material impacts the weight of the wheel. Lighter plastics are preferred for applications where weight reduction is essential, such as aircraft ground support equipment.

- 9. Noise Level: Some plastic materials are designed to reduce noise when in operation. They offer quieter movement, making them suitable for environments where noise reduction is a priority.

- 10. Cost: Material choice can affect the cost of plastic wheels. High-performance plastics often come at a higher price point, while standard plastics like polypropylene are more cost-effective.

The selection of the right plastic material depends on the specific demands of the setting and application. Engineers and manufacturers choose materials that align with the environmental conditions, load requirements, and performance expectations to ensure that plastic wheels deliver optimal results.

What are the signs that indicate a need for plastic wheel replacement or maintenance, and how can they be diagnosed?

Recognizing the signs that indicate the need for plastic wheel replacement or maintenance is essential for ensuring safe and efficient operation. Here are common signs and how they can be diagnosed:

- 1. Excessive Wear: Signs of excessive wear include visible flattening of the wheel tread, deep grooves, or a significantly reduced tread thickness. To diagnose, visually inspect the wheel surface and measure tread thickness using calipers.

- 2. Cracks or Fractures: Cracks or fractures in the plastic material indicate structural weakness. Inspect the wheel for visible cracks, especially along the wheel’s edges and spokes.

- 3. Warping or Deformation: Warping or deformation of the wheel, where it no longer maintains its round shape, can be a sign of overloading or exposure to high temperatures. Diagnose by visual inspection and measurement of wheel dimensions.

- 4. Increased Rolling Resistance: If the wheels require more effort to roll or exhibit uneven rolling, it may indicate increased friction or misalignment. Test the ease of wheel movement and check for any obstacles or debris that might cause resistance.

- 5. Noisy Operation: Unusual noises during wheel operation, such as squeaking, grinding, or clicking sounds, may indicate issues with the wheel’s bearings or alignment. Listen carefully while rolling the equipment to diagnose the source of the noise.

- 6. Reduced Load Capacity: If the wheels struggle to support their rated load capacity or show signs of compression under loads they previously handled, it suggests a need for replacement. Observe the wheels under load conditions to assess their capacity.

- 7. Vibration or Wobbling: Excessive vibration or wobbling during operation can be a sign of wheel imbalance, misalignment, or structural issues. Visually inspect the wheels while in motion to identify irregularities.

- 8. Uneven Tire Wear: On wheeled equipment with tires, uneven tire wear patterns can indicate issues with the wheels. Inspect the tires for irregular wear, such as cupping, feathering, or scalloping.

- 9. Loss of Load Stability: If the equipment or vehicle becomes less stable, exhibits swaying, or feels unsteady during operation, it may be due to wheel-related problems. Diagnose by assessing the overall stability of the equipment.

- 10. Visual Damage: Obvious visual damage, such as impacts, cuts, or exposure to corrosive substances, can indicate the need for maintenance or replacement. Regularly inspect the wheel’s surface for any visible damage.

- 11. Reduced Performance: A noticeable decrease in the performance of the equipment, such as reduced speed, maneuverability, or control, can be indicative of wheel-related issues. Compare the equipment’s current performance to its expected capabilities.

- 12. Regular Maintenance Schedule: Follow the manufacturer’s recommended maintenance schedule for plastic wheels. This proactive approach helps identify and address potential issues before they become critical.

- 13. Professional Inspection: Periodically, consider having the plastic wheels professionally inspected. Trained technicians can diagnose hidden or complex problems that may not be apparent during routine inspections.

Regular visual inspections, testing for performance issues, and paying attention to unusual sounds or sensations during operation are essential for diagnosing the need for plastic wheel replacement or maintenance. Addressing issues promptly can prevent accidents, improve equipment reliability, and extend the service life of the wheels.

What is a plastic wheel, and how is it different from other types of wheels?

A plastic wheel is a type of wheel that is primarily constructed using plastic materials. It differs from other types of wheels, such as steel or aluminum wheels, in several ways:

- 1. Material Composition: The most significant difference is the material used. Plastic wheels are made from various types of plastics, such as polypropylene, polyurethane, or nylon. In contrast, steel wheels are constructed from metal, and aluminum wheels are made from aluminum alloys.

- 2. Weight: Plastic wheels are generally lighter than their metal counterparts. This reduced weight can be advantageous for applications where weight savings are essential, such as in industries like automotive and aerospace.

- 3. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion, making them suitable for use in wet or corrosive environments. In contrast, metal wheels, especially steel wheels, are susceptible to rust and corrosion over time.

- 4. Cost: Plastic wheels are often more cost-effective to manufacture than metal wheels. This cost advantage can make plastic wheels an attractive option for various applications, including consumer products and industrial equipment.

- 5. Load Capacity: Metal wheels, especially those made from steel, tend to have higher load-carrying capacities compared to plastic wheels. Metal wheels are often used in heavy-duty applications where substantial weight-bearing capacity is required.

- 6. Durability: Metal wheels are generally more durable and have a longer lifespan, especially in high-stress or abrasive environments. Plastic wheels may wear out more quickly when subjected to heavy loads or rough surfaces.

- 7. Noise and Vibration: Plastic wheels can offer noise and vibration dampening properties, which can be advantageous in applications where reducing noise is essential, such as in office chair wheels.

- 8. Heat Resistance: Metal wheels typically have better heat resistance properties compared to plastic wheels. Metal wheels can withstand higher temperatures without deforming or losing structural integrity.

- 9. Aesthetic Options: Metal wheels, particularly aluminum wheels, offer a wide range of aesthetic options and finishes. This makes them popular in automotive and custom wheel applications where appearance matters.

The choice between plastic wheels and other types of wheels depends on the specific requirements of the application. Plastic wheels are often preferred for their lightweight, corrosion resistance, and cost-effectiveness, while metal wheels excel in heavy-duty and high-load applications.

editor by Dream 2024-05-03

China factory CHINAMFG Manufacturer Industrial 100mm 125mm 6 Inch Castor White PP Plastic 5″ Locking Caster Wheels

Product Description

Swivel caster with elastic blue rubber wheel+black nylon center 80*35

1. Wheel: High elastic bule rubber

2. Rim: Nylon

3. Colour: Blue rubber+black nylon rim

4. Hardness: 75A

5. Diameter: 80-200mm

6. Bearing: Roller bearing

7. Packing: Paper box, wodden box

COMPANY INFORMATION:

Xihu (West Lake) Dis. Xihu (West Lake) Dis. Plastic Products Co., Ltd. Is a professional large-scale manufacturer of all types of polyurethane wheel, rubber wheel and roller in China. Our main products include PU wheel, rubber wheel, roller, casters and related products. Our company Located HangZhou, we enjoy convenient water, land and air transportation.

Currently, Xihu (West Lake) Dis. Xihu (West Lake) Dis. Plastic Products Co., Ltd is exported to America, France, Australia, Italy and 20 other countries and regions. Our company has always focused on research, development and innovation, In 2006, we attained RoHS and Reach certification.

Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

ADVANTAGE:

1. hight load capacity.

2. any color can be made(white and black).

3. low rolling resistance,elastic abrasion resistant.

4. any quality nylon can be made.

SHIPPING & DELIVERY DATE:

1. 30%T/T deposit and 70% T/T CHINAMFG copy of B/L.

2. 25-30days after received the 30% deposit.

COMPANY INFORMATION:

Xihu (West Lake) Dis. Xihu (West Lake) Dis. Plastic Products Co., Ltd. Is a professional large-scale manufacturer of all types of polyurethane wheel, rubber wheel and roller in China. Our main products include PU wheel, rubber wheel, roller, casters and related products. Our company Located HangZhou, we enjoy convenient water, land and air transportation.

Currently, Xihu (West Lake) Dis. Xihu (West Lake) Dis. Plastic Products Co., Ltd is exported to America, France, Australia, Italy and 20 other countries and regions. Our company has always focused on research, development and innovation, In 2006, we attained RoHS and Reach certification.

Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

ADVANTAGE:

1. hight load capacity.

2. any color can be made(white and black).

3. low rolling resistance,elastic abrasion resistant.

4. any quality nylon can be made.

SHIPPING & DELIVERY DATE:

1. 30%T/T deposit and 70% T/T CHINAMFG copy of B/L.

2. 25-30days after received the 30% deposit.

Q:What Is Polyurethane?

A: Polyurethane is a synthetic material that is used in various applications in nearly every field imaginable. It is renowned for its durability and flexibility and can be produced in a number of different forms based on what it will be used for. Everything from airplane CHINAMFG to tires can be made with polyurethane.

·

Q: Polyurethane Identification

A: Polyurethane is identified as a polymer, which is basically a string of smaller molecules known as monomers. In this case, it is a string of urethane. An entire polyurethane chain consists of nitrogen, carbon and oxygen atoms double-bonded to a hydroxyl group, which is also known as an alcohol and is a bonded molecule of oxygen and hydrogen. When various other elements are added to this basic chain, the polyurethane changes, sometimes becoming a rubbery solid, liquid or even a foam.

Q: Polyurethane Features

A: Polyurethane can be manufactured synthetically to have a number of different features, depending on the specific molecules that are added to its basic string of urethane molecules. Some of the more sought-after features of polyurethane are its elasticity and durability. This makes it popular for use with tires and other rubber devices that need to be strong and bendable. Polyurethane can also be made into a squishy, foam-like substance or a substance similar to glue, with the same bonding ability.

Q Polyurethane Function

A: Polyurethane is used in so many different fields and in so many different forms that it is 1 of the most used synthetic materials. Look around your house, and you will be able to find many things that are made of polyurethane. Much of the firmer rubber used for various reasons is polyurethane, and because as an adhesive it is water and heat resistant, it’s used in outdoor and exceptionally hot areas. It is also used in walls as extra padding, and in foam form for soundproofing.

Q: Warning

A: For the most part, polyurethane is not a dangerous substance–which is why there is no limit on exposure to it. However, there are times where it can let off harmful chemicals, including carbon monoxide and other hazardous fumes. This is generally when polyurethane is heated to over 200 degrees C. For this reason, handling this polymer at high temperatures should be done with gloves and a personal breathing apparatus.

Q:Polyurethane Benefits

A: One of the major benefits of polyurethane is its resistance to heat and flames. Using the substance means that it will offer protection from this, which makes it particularly beneficial in the home and in making important substances and materials. It is often used as a coat for wood, plastic or other substances because of this protective property.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Swivel Caster with Rubber Wheel |

|---|---|

| Wheel Material: | Rubber |

| Brake: | Without Brake |

| Bearing Type: | Roller Bearing |

| Surface Treatment: | Nylon |

| Brand: | Tongzhou |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

Can you explain the primary functions and applications of plastic wheels in various industries?

Plastic wheels serve essential functions in various industries due to their unique properties and versatility. Here are the primary functions and applications of plastic wheels in different industries:

- 1. Material Handling: Plastic wheels are widely used in material handling equipment, including carts, dollies, and conveyor systems. They provide smooth and noiseless movement, making them suitable for transporting goods in warehouses, factories, and distribution centers.

- 2. Office Furniture: Plastic wheels are commonly found on office chairs and furniture. They allow for easy mobility, quiet operation, and floor protection. These wheels are often made from soft materials like polyurethane to prevent damage to flooring.

- 3. Automotive: In the automotive industry, plastic wheels are used for various applications, including caster wheels on tool carts, wheels for automotive jacks, and even lightweight spare tire wheels. They offer a balance of durability, weight savings, and cost-effectiveness.

- 4. Retail and Shopping Carts: Plastic wheels are a staple in retail and shopping cart applications. They provide smooth and silent movement for shoppers while navigating stores. The lightweight nature of plastic wheels reduces cart weight, making them easier to push.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, such as hospital carts and medical devices. Their non-corrosive properties, lightweight design, and ease of cleaning make them suitable for healthcare settings.

- 6. Aerospace: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft.

- 7. Food and Beverage: Plastic wheels are found in food service equipment, including food carts, serving trolleys, and food processing machinery. They are resistant to moisture and corrosion, which is critical in food handling environments.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and easy adjustment for leveling RVs and trailers when parked.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications. They can be found on hand trucks, utility carts, and DIY furniture, offering ease of movement and floor protection.

- 10. Marine and Boating: Plastic wheels are used on boat trailers and marine equipment. They resist corrosion from saltwater exposure and offer buoyancy, making them ideal for marine applications.

- 11. Agriculture: In agriculture, plastic wheels are used on farm equipment, including wheelbarrows and agricultural carts. They provide durability and easy maneuverability in outdoor and rugged environments.

Plastic wheels are valued for their lightweight, corrosion resistance, cost-effectiveness, and adaptability across a wide range of industries. They play a vital role in improving mobility, efficiency, and performance in various applications.

editor by Dream 2024-05-03

China best Plastic Rim High Load Capacity Low Price Rubber Powder CHINAMFG Rubber Wheels (8X1.75)

Product Description

10′ trash bin wheel

| Diameter: | 255mm |

| Hole diameter: | 22mm |

| Hub length: | 80mm |

| Load Capacity: | 100kg |

Specifications:

Diameter: 260mm

Hub length: 70-74mm

Hole diameter: 16mm/20mm

Load caoacity: 100kg

Tread pattern: Straight line, cross, big square, turf, flower and so on

Product Pictures:

Exhibitions:

Why Choose Us

01. Professional production and sale team to delivery on time

02. 7*24 Hours Pre-Sale and After-Sale service

03. We accept small order to check our quality

04. We accept OEM and ODM design

05. Free sample for all orders

06. We had the honor to service some of famous corporation

Packing:

1). Packing: Packed in Bulk,Polybag,Carton ,Pallet.as customer request

2). Price Terms: FOB,CFR,CIF

3). Payment term:30% TT deposit in advance,the balance before shipping.T/T or L/C.

4). Delivery Port: HangZhou Port,China

5). Leading Time: With 20-35days after receiving the deposit

FAQ:

1. Are you a factory or a trading company?

HangZhou CHINAMFG Special Hand Truck CO., LTD. is a professional export-oriented head marketing factory.

2. Is OEM available?

Yes, OEM is available.We have professional worker to help your brand promotion.

3. Is the sample available?

Yes, samples are available for you to test the quality,but please bear the express charges .

4. Are the products tested before shipping?

Yes, all of our ATV tire,pneumatic wheel ,PU wheel ,and CHINAMFG wheel were qualified before shipping. And we test every batch every day.

5. Whats your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

If you have any questions, please feel free to contact with us.

We will provide 24-hour online service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Color: | Multi-colored |

| Type: | Fix Wheel |

| Surface Treatment: | Chrome Plated |

| Size: | 8′ |

| Material: | Plastic |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What advantages do plastic wheels offer in terms of corrosion resistance and longevity?

Plastic wheels offer several advantages in terms of corrosion resistance and longevity, making them a preferred choice in various applications:

- 1. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion. Unlike metal wheels, which can rust or corrode when exposed to moisture or harsh chemicals, plastic wheels do not rust or corrode. This corrosion resistance is especially valuable in wet or corrosive environments.

- 2. Chemical Resistance: Plastic wheels can withstand exposure to a wide range of chemicals, acids, and solvents without deteriorating. This resistance to chemical damage extends their lifespan when used in environments where chemical spills or exposure is a concern, such as in laboratories, manufacturing facilities, or healthcare settings.

- 3. Moisture Resistance: Plastic wheels are not affected by moisture, making them suitable for outdoor applications or environments with high humidity. They do not absorb water, preventing swelling, warping, or degradation due to moisture exposure.

- 4. UV Resistance: Some plastic materials used for wheels are UV-resistant, which means they can withstand prolonged exposure to sunlight without degrading or becoming brittle. This quality is beneficial for outdoor applications, including lawn and garden equipment.

- 5. Longevity: Plastic wheels are designed for durability and a long service life. High-quality plastics, reinforced designs, and proper maintenance contribute to their longevity. They do not suffer from wear and tear like rubber or pneumatic tires and can maintain their performance over extended periods.

- 6. Low Maintenance: Plastic wheels typically require minimal maintenance. They do not need lubrication, and their surfaces are easy to clean. This reduces the need for ongoing maintenance, saving time and resources.

- 7. Lightweight: Plastic wheels are lightweight compared to many metal alternatives. Their reduced weight places less stress on equipment, reducing wear and tear and contributing to their overall longevity.

- 8. Non-Marking: Some plastic wheels are designed to be non-marking, meaning they won’t leave scuff marks or damage flooring surfaces. This feature is valuable in applications where protecting the floor’s appearance is important.

- 9. Floor Protection: Plastic wheels, especially those with softer materials or specialized coatings, provide excellent floor protection. They are gentle on surfaces and do not scratch or dent floors, making them ideal for indoor use.

Overall, the corrosion resistance and longevity of plastic wheels make them an excellent choice for applications where environmental factors, chemicals, or moisture could compromise the performance and lifespan of other wheel materials, such as metal or rubber.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

In what scenarios are plastic wheels commonly used, and how do they compare to metal wheels?

Plastic wheels find common usage in various scenarios due to their unique characteristics. Here are scenarios where plastic wheels are commonly used, along with a comparison to metal wheels:

- 1. Indoor Material Handling: Plastic wheels are often preferred for indoor material handling equipment, such as carts and dollies. They offer quiet and smooth operation, making them suitable for use in warehouses and factories. Compared to metal wheels, plastic wheels are quieter and less likely to damage indoor flooring.

- 2. Office Furniture: Plastic wheels are commonly used on office chairs and furniture. They provide ease of movement, floor protection, and a quiet glide. In contrast, metal wheels can be noisy and may damage flooring surfaces.

- 3. Light-Duty Automotive Applications: In automotive applications, plastic wheels are used for lightweight components like automotive jacks and tool carts. They offer a balance of durability, weight savings, and cost-effectiveness. Metal wheels, on the other hand, are used for heavy-duty automotive applications.

- 4. Retail and Shopping Carts: Plastic wheels are standard in retail and shopping cart applications. They provide a smooth and quiet shopping experience and reduce the effort required to push carts. Metal wheels are less common in this scenario due to their noise and potential to damage store floors.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, where cleanliness, non-corrosiveness, and ease of cleaning are essential. Metal wheels may not be suitable due to corrosion concerns and potential difficulty in sterilization.

- 6. Aerospace Ground Support: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft. Metal wheels are used in some heavy-duty ground support applications.

- 7. Food and Beverage Handling: Plastic wheels are used in food service equipment, as they resist moisture and corrosion. They are ideal for food carts, serving trolleys, and food processing machinery. Metal wheels may not be suitable in food handling due to corrosion risks.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and ease of adjustment for leveling RVs and trailers when parked. Metal wheels are not common in these applications.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications, such as hand trucks and utility carts. They offer ease of movement and floor protection. Metal wheels are less favored in these scenarios due to potential noise and floor damage.

When comparing plastic wheels to metal wheels, the choice depends on factors like load capacity, durability, noise level, and the specific application’s requirements. Plastic wheels excel in scenarios where lightweight, quiet operation, and floor protection are essential, while metal wheels are preferred for heavy-duty applications with high load requirements.

editor by Dream 2024-05-02

China Custom OEM Natural Cork + ABS Plastic Custom Design Yoga Wheel

Product Description

OEM Natural Cork + ABS plastic Custom design Yoga Wheel

Surface Material Choice: PU, Microfiber, Cork or TPE

Yoga Accessories

Product Description

Packaging & Shipping

Default Yoga Wheel Package

Each wheel will be wrapped with bubble wrap and placed individually in a ready-to-ship cardboard box.

Every 3 or 6 wheels will be placed into cartons for final shipping.

General Shipment information

Shipping time and cost varies dramatically by ordering amount, destination country, product type and delivering method. We can ship our goods to your designated freight forwarder, or we can arrange our contracted freight CHINAMFG to offer DDU service to you.

Please be sure to provide a detailed inquiry when requesting shipping information in order to get an accurate estimation. Generally, we would like to know product type, ordering amount, your destination address or port, and level of service you want us to provide (DDU or to the port or to your freight forwarder) to obtain a quote from our freight forwarder.

Our Services

FAQ

Question 1: Can you design for us?

We have a professional designing team to satisfy your design needs.

Question 2: This is our first time exporting/importing, can you handle transportation for us?

We have agent service for our customer and we offer DDU service, meaning we can send the goods to your doorstep while the only thing you have to worry is duty and tax of your own country. If you need more information, please feel free to contact us.

Question 3: What is the regular MOQ for your product?

Different products will have different MOQ, but generally speaking, 100 pieces is a common MOQ.

Question 4: What’s your payment term?

Regularly we collect 30% of the total balance as a deposit when order is placed, and the remaining 70% will be collected before shipment. All payments are by TT. However, based on your specific situation we will be able to negotiate for a different method. If you have any special request, please do not hesitate to contact us.

Question 5: What is your quality control process?

We have a professional QC team who monitors the production process, while all finished goods will be inspected before shipment to meet our standard. Unqualified goods will be collected and discarded.

Question 6: If we don’t have any shipping forwarder in China, could you do this for us?

Yes. We partner with professional shipping forwarder who has been working with us for more than 10 years. If you don’t have any shipping forwarder, you will still get the best shipping price excellent service from our partner.

Question 7: How can we get updates for new products?

Let us know what kind of product you are interested in, and we can provide you weekly updates for the newest addition in our product portfolio.

Question 8: If we want to develop new products based on general ideas, would you be able to assist?

Our R&D team is ready to help in turning your idea into a real product starting from scratch. If you decide to put mess production order in we can even waive molding cost for you.

Question 9: I have never been to China before, would you be able to offer factory tour and maybe a city guided tour for me?

We can arrange to pick you up from the airport to our company and to book accommodation for you. Our customer service team will be happy to guide you for a tour of the city or even nearby factories/ trading hub. Please let us know your plan, and we are here to help. English translation will be provided along the way CHINAMFG request – so no need to worry even that’s your first time going abroad!

Question 10: I can’s speak Chinese or English, can you find 1 translator for me?

Simply let us know which language you prefer, and we can arrange for a translator.

Our Company

Our Story

HangZhou Jukui Electronic Technology Co., Ltd has been in business starting 1995, with our first manufacturing plant built in HangZhou. With increasing demand and developing business, we moved into our current factory in 2008. Located in the beautiful city HangZhou, our 2500 square meters’ factory is equipped with profession production lines and advanced manufacturing machines to suit every customer’s unique needs. Strictly managed by ISO-9001 Quality System, we offer only the best quality goods, while our professional supply chain team strives to follow your timeline for on-time delivery.

Our Product

Rubber mats of all kind. With different surface material, thickness and size we are able to offer a huge selection of rubber mats for customization. From mouse pads, yoga mats to oversize gaming mats, 1 can almost always find a solution for their unique needs. We offer different surface material including PU, microfiber, cork, and PVC (no rubber base), which gives our customer unlimited possibility on developing mats for different uses. We also welcome OEM orders, in which our strict testing method and reasonable price will ensure that your design comes out exactly as you wish it to be.

Our Team

We have over 100 team members dedicating to provide our customer best service as they can. Our production team is supported by a design lab, quality control manager and R&D staff, all led by a professional manufacturing manager who has been with our company since day 1. We also have a customer service team that can take care of all your importing question as well as communication between the customer and production team. We offer professional service in both English and Chinese, and we can always translate the language you use to ensure smooth communication.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Kind: | Wheel |

|---|---|

| Material: | ABS & Cork |

| Color: | Solid Color |

| Age: | Adult |

| Gender: | Unisex |

| Type: | Yoga Equipment |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do plastic wheels fare in terms of weight-bearing capacity compared to other materials?

Plastic wheels have weight-bearing capacity that varies depending on factors such as the type of plastic used and the wheel’s design. Compared to other materials like metal, here’s how plastic wheels generally fare in terms of weight-bearing capacity:

- 1. Light to Medium Loads: Plastic wheels are well-suited for light to medium loads. They can typically support loads ranging from a few pounds up to several hundred pounds, depending on their design and construction. For applications such as office chairs, hand trucks, and smaller carts, plastic wheels are often sufficient.

- 2. Heavy-Duty Loads: When it comes to heavy-duty loads, metal wheels, particularly steel and cast iron wheels, are preferred. Metal wheels can handle much heavier loads compared to plastic wheels. In industrial settings, where loads can exceed a thousand pounds or more, metal wheels provide the necessary strength and durability.

- 3. Load Distribution: Plastic wheels may perform well in load distribution when used in sets or pairs. Distributing the load across multiple plastic wheels can increase their effective weight-bearing capacity. However, metal wheels still excel in heavy load-bearing scenarios.

- 4. Reinforced Plastic Wheels: Some plastic wheels are designed with reinforced materials, internal structures, or additional support to enhance their weight-bearing capacity. These reinforced plastic wheels can handle heavier loads than standard plastic wheels but may not match the load capacity of metal wheels.

- 5. Material and Design: The choice of plastic material and the wheel’s design significantly impact its load capacity. High-quality plastics like nylon and polyurethane tend to have better load-bearing capabilities compared to softer plastics like polypropylene. Additionally, factors such as wheel diameter and tread design play a role in load-bearing capacity.

- 6. Application Considerations: The suitability of plastic wheels for weight-bearing also depends on the specific application. For applications where load capacity is a critical factor, such as heavy machinery or industrial equipment, metal wheels are typically chosen to ensure safety and reliability.

In summary, plastic wheels are suitable for light to medium loads in various applications. They offer benefits such as corrosion resistance, quiet operation, and floor protection. However, for heavy-duty applications with substantial loads, metal wheels, particularly steel and cast iron wheels, are preferred due to their superior weight-bearing capacity and durability.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

Can you describe the factors to consider when selecting plastic wheels for specific applications?

Selecting the right plastic wheels for specific applications involves considering several crucial factors to ensure optimal performance and durability. Here are the key factors to keep in mind:

- 1. Load Capacity: Determine the weight that the wheels will need to support in your application. Choose wheels with a load capacity that comfortably exceeds the maximum expected load to prevent overloading and premature wear.

- 2. Wheel Diameter: The diameter of the wheel affects its stability, ease of rolling, and ability to overcome obstacles. Select a wheel diameter that suits the terrain and surface conditions in your application.

- 3. Tread Design: Consider the tread pattern on the wheel. Smooth treads offer lower rolling resistance, while treaded or ribbed designs provide better traction. Choose the tread type that aligns with your application’s requirements.

- 4. Material Selection: Plastic wheels are available in various materials, such as polyurethane, polypropylene, and nylon. The choice of material should consider factors like durability, impact resistance, chemical resistance, and temperature resistance based on your application’s environment.

- 5. Bearing Type: Determine the bearing type used in the wheels. Precision bearings, like ball bearings or roller bearings, reduce friction and ensure smooth rolling. Choose bearings appropriate for your application’s load and usage frequency.

- 6. Environment: Assess the operating environment. Consider factors such as exposure to moisture, chemicals, extreme temperatures, and potential corrosion. Select wheels that are suitable for the conditions they will encounter.

- 7. Floor Protection: If your application involves rolling on delicate flooring, consider wheels with softer materials or non-marking properties to protect the floor from damage or marking.

- 8. Mobility and Maneuverability: Evaluate the required mobility and maneuverability of your equipment or vehicle. Swivel casters may be needed for tight spaces, while fixed wheels offer stability in straight-line movement.

- 9. Noise Level: Consider the noise level generated by the wheels. Some applications, like office furniture, require quiet operation. Choose wheels designed to minimize noise if noise is a concern.

- 10. Maintenance: Assess the maintenance requirements of the wheels. Some wheels may require regular lubrication or cleaning, while others are low-maintenance. Ensure that the maintenance demands align with your operational capabilities.

- 11. Mounting and Attachment: Check the compatibility of the wheel’s mounting and attachment method with your equipment or vehicle. The design should securely attach to prevent wobbling or detachment.

- 12. Budget: Consider your budget constraints. Different types of plastic wheels come at various price points. Balance your budget with the need for quality and durability.

By carefully evaluating these factors and selecting plastic wheels that align with your specific application’s requirements, you can ensure that your equipment or vehicle operates optimally, efficiently, and safely.

editor by Dream 2024-05-02

China manufacturer Beach Cart Wheel Inflatable Pneumatic Air Rubber Tire Wheels with Metal Rim or Plastic Rim

Product Description

rubber wheel for forklift

1.Wheel: high elastic rubber

2.Rim: aluminum

3.Colour: black

4.Hardness: 75A

5.Diameter: 180mm

6.Bearing: 6204ZZ

7.Packing: Paper box,wodden box

ADVANTAGE:

1. any hardness can be made.

2. hight load capacity.

3. good bonding for pu with wheel center.

4. low rolling resistance,elastic abrasion resistant.